RS Blog 19 - Suspension Geometry, Weights and Foot Defense Devices

First things first…. I need to know how much all the suspension parts weigh, because curious and well I need to understand how it will work. My car has the standard AP Racing 4 piston calipers on all four corners coupled with drill rotors and rose joint suspension.

Only concerned with fronts for now because of lift kit and attempting to manage lower vs raised shock position. Depending on conditions you’ll want the shock between 40-60% of its travel allowing for bump compliance and general good manners on shitty roads.

Too low runs risks of using shock as a solid suspension component during bumps, while too high leads to the shock serving as a limit strap. Neither are nice to the shock or ride quality.

The front Nitron shocks have 3.0” of overall travel with a 1” bump stop, leaving 2” of free shock travel before encountering the bump stop. I’m okay with using the bump stop occasionally so will assume 1/2” of it is allowable to use when calculating shock and spring travel.

Lift kit moves the spring perch by 1”. I’d like if possible to drive around at low speeds with the lift fully engaged and prevent minor scrapes/hits on chassis.

Doing some simple math and it seems my shock normal ride height should be around 50-60% of its travel to minimize both ride height situations. Not sure what this means for chassis ride height, definitely will fine tune later. For now I can see if a 5” shock works better than the standard 6” and if I should adjust any spring rates from the offered 600 lb. Working through acceptable spring travel before coil bind considering the shock travel and it seems a 5” spring will be fine and allow easier mounting of the shocks with the hydraulic lift. Ultima recommends removing the lock ring to install and I just don’t like that idea when there is a hydraulic line attached to the lower perch.

For now just pondering, but may order a set of 5” springs for fronts. Images below show the inability to reinstall upper perch without a spring compressor while the lower lock ring is present…

Weights you probably didn’t care about, but I do!

Sprung Weight

Wheel - 23.2 lbs

Tire (estimated) - 22 lbs

Rotor - 16.6 lbs

Hub with lug nuts - 12.0 lbs

Caliper (4 piston) - 9.0 lbs

Semi-Sprung Weight

Suspension Arms - 8.6 lbs

Shock/Spring - 5.0 lbs

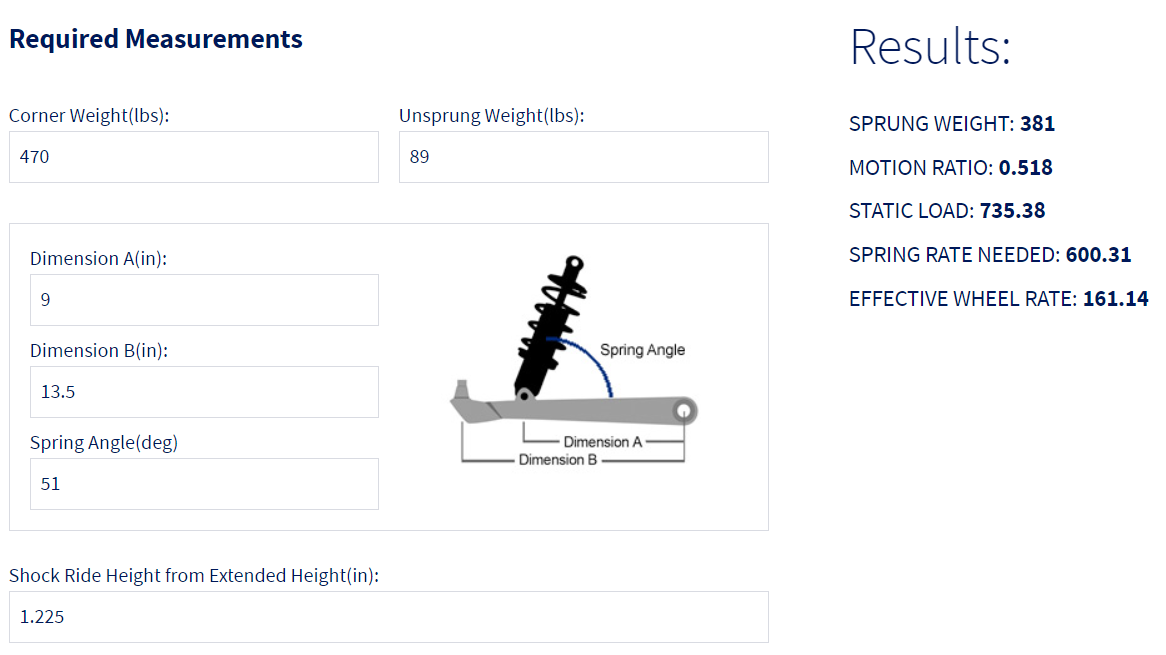

Using online spring calculator from Hyperco yields a 600 lb spring should sag approximately 1.22”. So we are in ball park to keep shock happy. This does assume the weight distribution is around 45% front / 55% rear. Entirely a guess for mid-engine car.

Below is the front suspension geometry as measured, yielding a roughly 47-55° angle between suspension arm and shock for the calculations. Using a middle of road 51° for calculations.

Isolating the Electrons via other Electrons

While this is technically a street car I am building it with track oriented safety features, this includes a battery kill switch. I don’t have any idea on where to mount a big bulky standard switch, but opted for a nice Cartek electronic version. Installed module in a solid spot above the steering rack with copper anti-seize. Later I can install the button in body panel that makes sense and add stickers to be ‘race car’.

While mounting this I found some rubber grommets that will seal access holes for mounting bolts and I’ll leverage them on steering rack holes. Can’t have any water or debris filling up the chassis holes.

If you are curious, they can be found at McMaster-Carr. Part #9750k91.

Finally we can’t have feet intermingling on track

This is a simple modification to the foot rest supplied by Ultima. The foot rest is really nice, but I didn’t want any passenger feet sliding into my accelerator pedal mid corner. Simple addition of aluminum solves the risk. Very happy with outcome.

In case you noticed the missing brake pedal….the new design is on the way!

Miles of Wires

The re-wiring of chassis is in progress, nothing to exciting. Just sharing how long the Haltech 5 meter universal harness actually is. Just hilarious. Exactly what I needed and they have multiple voltage sources and grounds as part of harness so I won’t need to add anything, just run to sensors and terminate on connectors! Loving the Haltech hardware.