RS Blog 9 - Fitting the First Hardware

Finally starting to play with actual parts instead of just pesky rivets. One of the items revolved around confirming radiator alignment and checking final holes in double skin option. Another likely more important piece was dealing with brake pedal ratios and deciding on a pathway forward that hopefully avoids cutting out parts to add a Tilton pedal box. Lots of Ultima owners/builders have complained about inadequate brake bite/feel/stopping power. This mostly seems to come down to the pedal ratio provided by factory. Time to bust out some engineering and prototyping.

Brilliant Idea!

Instead of being like everyone else and slapping in some shiny race car parts, I’ll engineer a solution using factory brackets. It allows the chassis powder coat to stay intact and minimizes any strength reduction from cutting/fitting. A little research and I found the Girling master cylinders have a similar size (0.625” and 0.75”) to those available from Tilton, if anything I can likely swap them later to fine tune things.

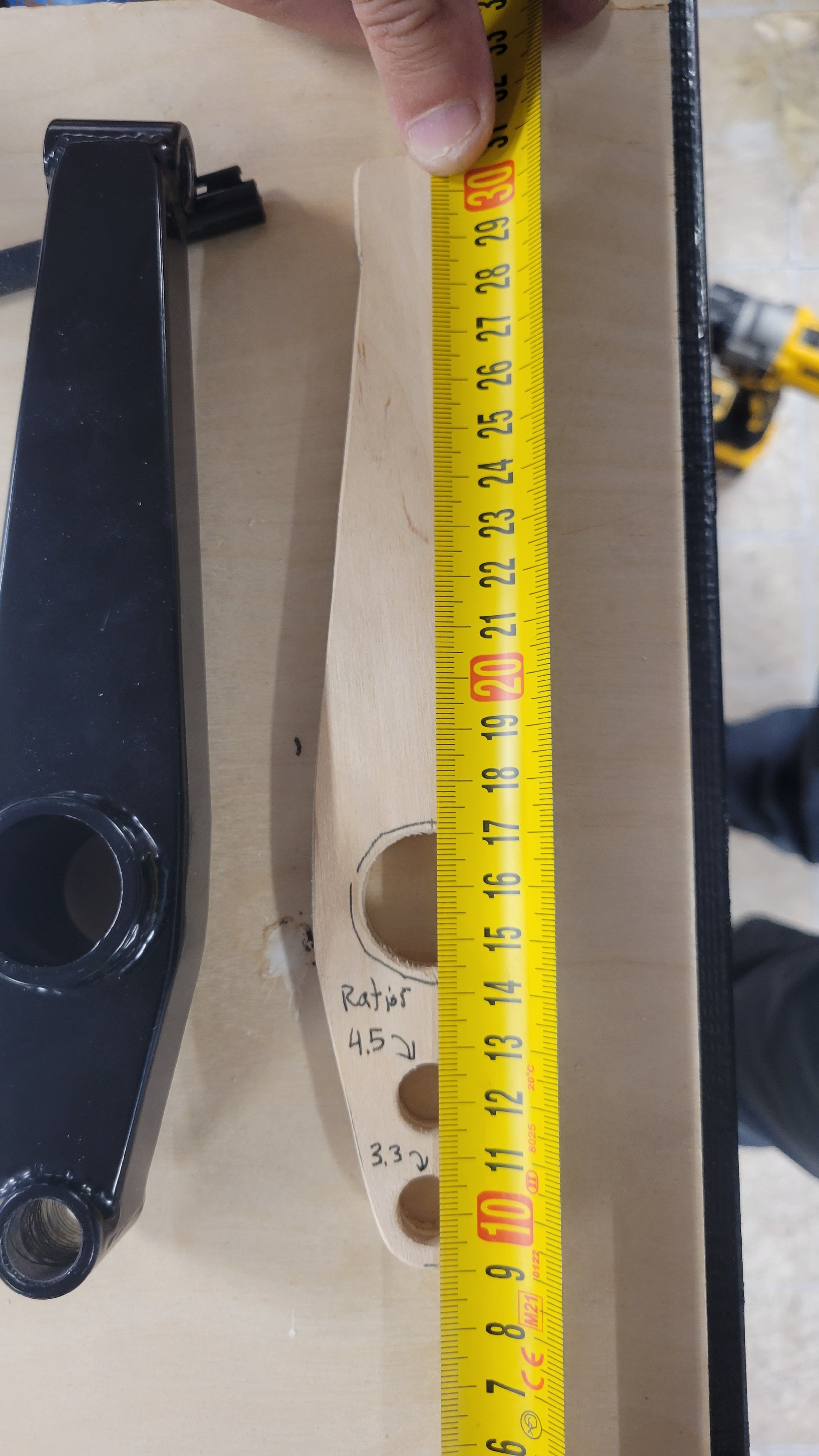

The idea is simple, create a shorter pedal pivot to increase the ratio from 3.3 to near 4.5-5.2 (almost matching a Tilton floor mount box). Goal is to retain the pedal position and keep balance bar to pedal length while reducing pivot to balance bar length. There is enough space between the existing points to create a set of adapter brackets that are secured to the stock mount and create a new pivot offset point 20-25 mm higher.

End goal is to cut and re-weld/powder coat the stock pedal, plus have a pair of brackets machined. Some CAD drawings will be added to this page soon.