Eyeball the Oil Line Routing

Tonight the task was figuring out where these oil lines for the dry sump system would actually fit inside the tiny miata. My main goal is to keep everything tidy and away from heat as much as feasible. The most important part of a clean installation is the beer/thought used to create it.

To start I needed to understand the correct plumbing and thus searched AVIAID’s website to find it. We are going to be running the 3 stage LS ‘C’ system. With limited space I’ll plan on running a single scavenge return line.

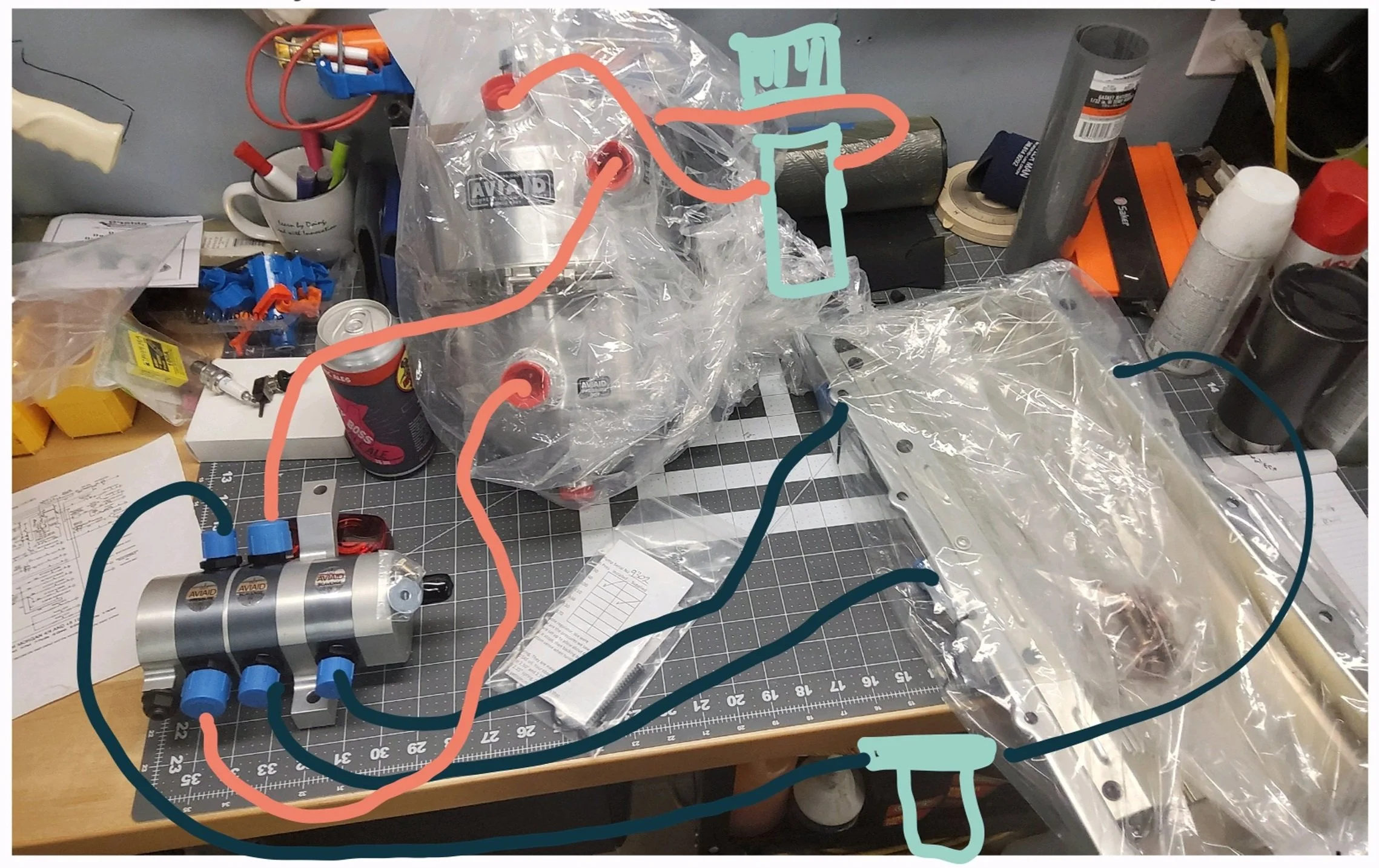

Breaking out the doodling via the tablet!

Translating the manufacturer diagram into my collection of parts. I’ve annotated the oil breather and existing remote filter. I thought I would be able to move the filter to the trunk, but alas it will remain hidden in the fender. This will help me with mounting and at least a single AN-10 oil line since the existing setup ran from the fender to oil pan.

In the ‘diagram’ below I’ve noted AN-12 lines in light red and AN-10 with dark blue.

This should mean I only need to run a pair of AN-12 lines from the engine bay to the trunk. Hopefully via the transmission tunnel…

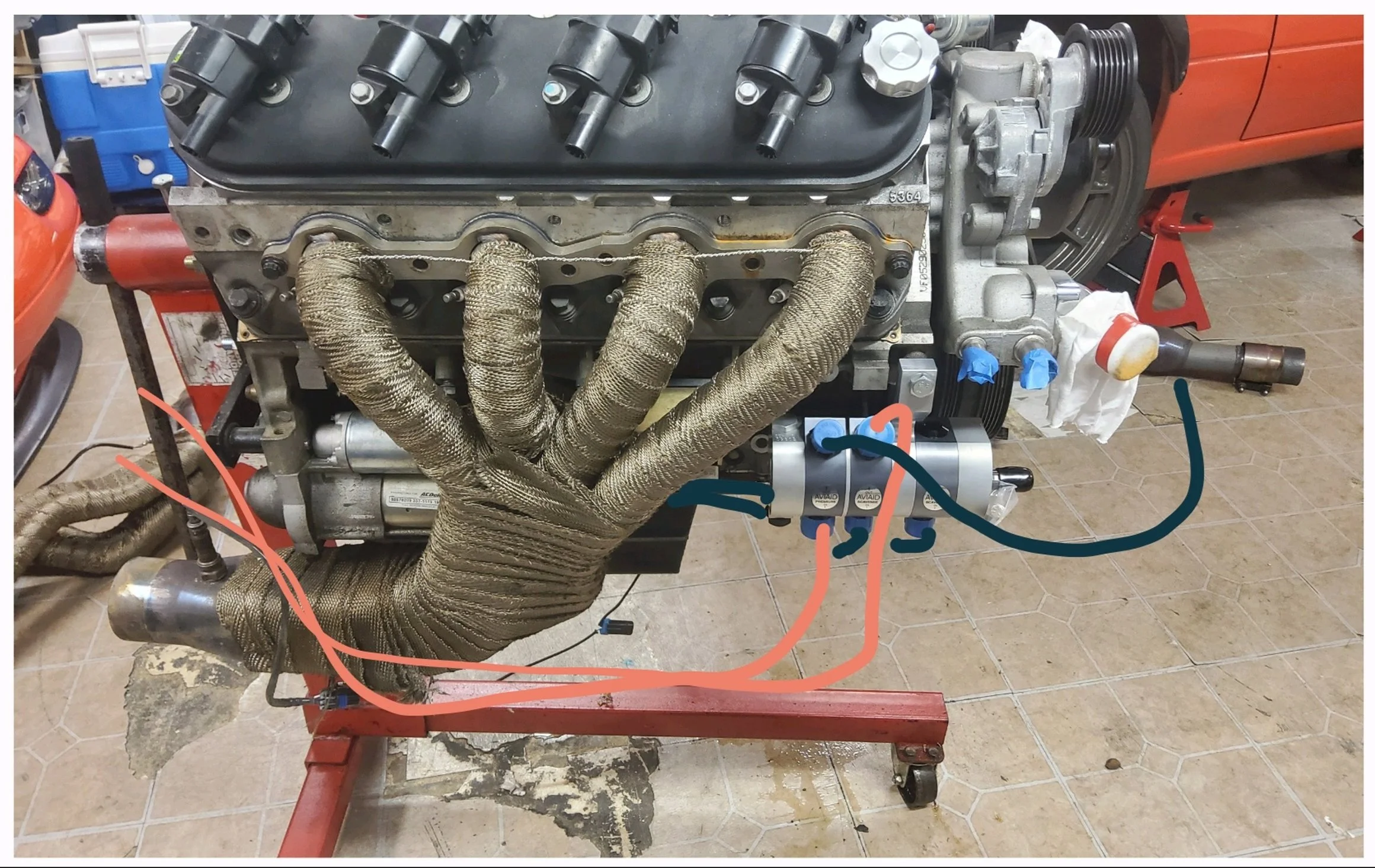

Just look at that monster of a header. It took me quite awhile to wrap it so tightly and I’m very happy it has held up well with only the safety wire across the main tubes.

But the focus should be on the new sketches for oil lines. I am thinking I’ll be able to route the scavenge lines (AN-10) up against the pan and minimize their length without getting too close/hot to the collector. Main pressure line (AN-10) will be routed via a 45° toward the front.

The tricky ones are going be my pair of AN-12 lines toward the rear of the car. My current plan is to tuck them under the subframe and up around the header through the top of the transmission tunnel. It may involve some modification to the existing firewall to accommodate, but this is much safer and “easier” than trying to run through the passenger compartment. I’ll find out after I mock it up…

My priorities when routing lines are:

Minimize bends

Minimize heat source interaction

Maintenance

Light Red: AN-12

Dark Blue: AN-10

Ordering Parts!!

Based on my assumptions above these are my first order:

30’ of AN-12 hose

6’ of AN-10 hose

3x90° AN-10 hose to female fitting (oil pan)

2x90° AN-10 hose to female fitting (pump scavenge in)

1x45° AN-10 hose to female fitting (pump pressure out)

1x90° AN-12 hose to female fitting (pump pressure in)

1x120° AN-12 hose to female fitting (pump scavenge out)

3x90° AN-12 hose to female fitting (tank)

Once parts arrive more fitment is in the plan. I’m sure I’ll change it up a bit, but for now I think this is a solid plan.